Welche Lichttechnologie für meinen Endoskop-Einsatz?

Wärmebild, UV, Infrarot – und welche Geräte von EVi Scopes dafür die richtige Wahl sind Wer schon mal mit einem Endoskop...

Read nowCategories

About EVi Scopes

Who We Are

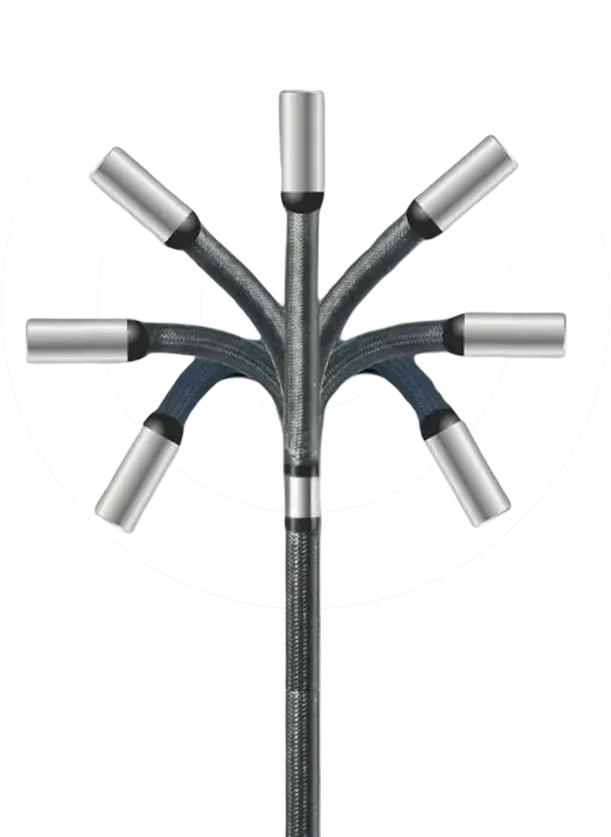

EVi Scopes develops and delivers inspection systems for everyone who needs to test precisely and reliably. Everything revolves around one thing: providing you with the right technology to see exactly what you need. Whether for pressure vessel testing, non destructive testing or plant maintenance – we develop and deliver industrial endoscope and endoscope camera systems that simply work in everyday operations. No frills, but with everything you need.

Passionate about what we do

When it comes to pressure vessel testing, every detail counts. But how do you inspect a tank without completely disassembling it? Our industrial borescope and flexible endoscope systems deliver clear images – even in places that would otherwise remain hidden. Whether LPG tanks, compressors or mobile containers: You see what's happening – and can document exactly what the TÜV or inspection authority needs to see.

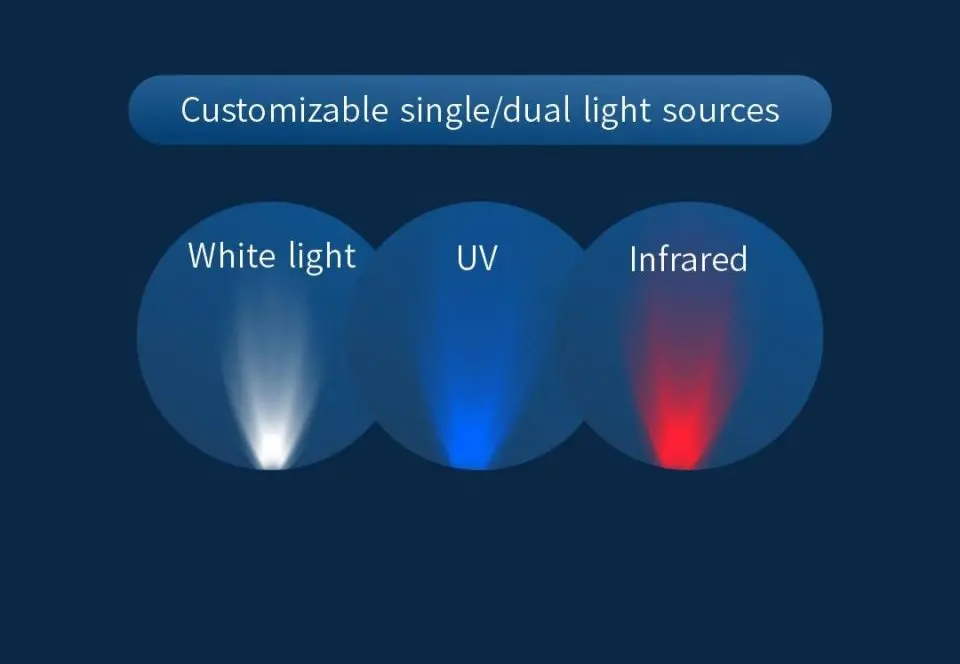

View More Request inspectionSome things you want to test without breaking them. Non destructive testing is the right approach – and our ndt inspection equipment helps you do it. Crack detection with uv inspection light? Internal surface inspection after production? Visual inspection during recurring maintenance? All possible – with the right light, the right optics and a system that works.

View More Request inspectionWhen machines run, things usually go well – until suddenly they don't. And then it gets expensive. With our video borescope systems, you can check early: corrosion, wear, deposits – small anomalies before they become real problems. And the best part: you can get to places no one else can – without unscrewing everything.

View More Request inspectionWhat comes out at the end must be right. Period. Especially in quality assurance, it has to be perfect. Welds, drill holes, internal walls – everything must be correct. Our industrial endoscope and camera systems provide you with a sharp, documentable image. Ideal for final inspection or intermediate testing in production.

View More Request inspectionEVi Scopes Serves Everyone

Internal views of machines, systems and pipeline systems – non-destructive, directly documentable and ideal for narrow or hard-to-reach places in operations.

Making the finest structures visible – for technical testing or preparation of devices, such as endoscope camera reprocessing or cleaning control.

Maintenance, testing and analysis of engines, components or interiors – precise, safe and without removal, even with tight tolerances.

Regular visual inspections help prevent downtime. With the right remote visual inspection technology, you can detect deposits, material wear or damage early.

Safe inspection in pipes, tanks or valves – even in heat, humidity or limited access. Technology that can withstand harsh conditions.

Whether corrosion control in the engine room or visual inspection below deck – ideal for hard-to-reach areas on board and in shipyards.

Whether industrial endoscope, uv inspection light or camera system – we deliver what you need for your visual inspection. Tailored to your needs. Direct, robust, reliable. Get expert advice now. We help you select and properly apply your inspection technology.

More than just a clear view

Especially with pressure vessel testing or machine maintenance: Those who see early what's changing can act in time.

No paper chaos, no follow-up submissions – results can be saved, traced and presented directly. Especially important for proof to authorities or customers.

In quality assurance, the difference between “looks good” and “is flawless” sometimes makes all the difference. Good images help with decision-making.

When multiple people inspect together – live or with saved images – decisions can be made faster and clearer. That saves time and nerves.

Because we want to inspire you every day

Extended Warranty for Greater Security

There are areas you simply can't reach with a screwdriver. Narrow pipes, sealed cavities, hard-to-reach machine areas – all places where you would previously have had to disassemble for hours. With our inspection cameras and articulating borescope systems, it's easier. Without disassembly, without interruption. You see exactly what you need to see – live, documentable and directly on-site. This not only saves time but often unnecessary downtime and expensive repairs.

Industry 4.0 sounds like the future – but it's already everyday reality. Also in visual inspection equipment. Modern video borescopes today are not just image providers, but part of a digital workflow. Images and videos can be saved, commented on, shared – directly from the device. Test reports are created automatically, live images can be streamed. This turns every inspection into a clearly documented process.

Get advice nowQMS

Reliable Quality Through Standards & Norms

Quality is not a buzzword for us, but a fixed part of our daily work. Our Quality Management System (QMS) meets all national and international standards and norms. This way our customers can be sure that every service and every test procedure meets the highest requirements.

Over 25 Years of Experience in Quality Assurance

For more than a quarter century, we've been specialists in the field of non destructive testing. This experience makes us a partner who can address almost any requirement. Together with our customers, we develop tailored solutions to efficiently, sustainably and safely master quality problems.

Quality as a living process

Our strength lies not only in conducting tests, but also in establishing quality standards in companies. With our expertise, we support companies in improving processes, minimising risks and increasing safety at all levels.

Innovation through specialised testing equipment

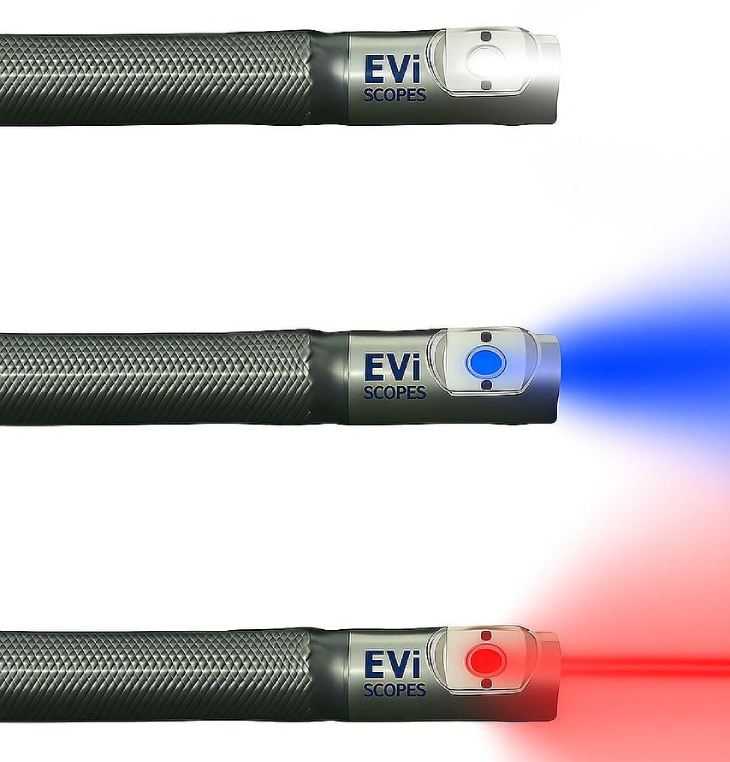

Another component of our quality promise is our specially developed high-tech equipment, which greatly facilitates testing processes. Particularly noteworthy are our innovative videoscopes with dual UV and white light systems, which make inspections more efficient and precise. With this combination of experience and innovation, we create clear added value for our customers.

Your partner for the highest quality standards

With our QMS, decades of experience and innovative solutions, we are ideally positioned to support your company in all matters relating to quality assurance – reliably, competently and with a view to the future.

Our exclusive blog

Wärmebild, UV, Infrarot – und welche Geräte von EVi Scopes dafür die richtige Wahl sind Wer schon mal mit einem Endoskop...

Read now

Ein Vergleich der Serien 2960, 2970 und 2980 von EVi Scopes – verständlich, ehrlich und anwendungsnah Wer in der zerstör...

Read now

Wie Sie gutes Equipment erkennen und welche Systeme sich in der Praxis bewähren In der Industrie reicht ein kurzer Blick...

Read nowFAQ

Because many people are interested: Here you will find practical answers to frequently asked questions about our product portfolio and our services – explained in an understandable way, directly from practical experience.

Questions? We are happy to help.Ein Videoendoskop ist im Grunde Ihr verlängerter Blick – für Stellen, an die Sie sonst nie rankommen würden. Das Gerät besteht aus einer Kamera am Sondenkopf, einer Lichtquelle und einem flexiblen (oder starren) Schaft, der dorthin führt, wo’s eng wird. Das Bild sehen Sie live auf einem Bildschirm. Das hilft zum Beispiel bei der Sichtprüfung von Rohren, Anlagen, Hohlräumen – überall dort, wo „einfach mal reinschauen“ eben nicht geht. Videoendoskope kommen oft bei der zerstörungsfreien Prüfung oder bei der Druckbehälterprüfung zum Einsatz. Und das Schöne: Man sieht sofort, was Sache ist.

Das Ganze nennt man Videoendoskopie. Sie brauchen keine aufwendige Demontage, keine Spezialkamera und auch keine Taschenlampe. Das Bild wird direkt auf ein Display übertragen, viele Systeme bieten auch Aufnahme- oder Zoomfunktionen. Besonders hilfreich ist das bei regelmäßigen Wartungen, Prüfungen oder dann, wenn Sie etwas dokumentieren müssen – etwa für den TÜV. Und je nach Modell können Sie sogar zwischen Weißlicht, UV oder Infrarot wechseln.

Eigentlich immer dann, wenn Sie wissen möchten, was im Inneren passiert – ohne gleich alles auseinanderzunehmen. Typische Einsatzfälle sind z. B. die Druckbehälterprüfung, die Kontrolle von Schweißnähten, die Wartung von Maschinen oder die visuelle Überprüfung bei der zerstörungsfreien Prüfung. Auch bei Rohrleitungen, Turbinen oder in der Qualitätssicherung kommt ein Videoendoskop regelmäßig zum Einsatz. Sie sparen Zeit, vermeiden unnötige Reparaturen – und haben ein echtes Bild vor Augen, statt nur eine Vermutung. Gerade in engen oder sensiblen Bereichen kann das den Unterschied machen.

Ob für einfache Sichtprüfungen oder anspruchsvolle Inspektionen in der Industrie – bei uns finden Sie genau das Endoskop, das Ihre Anforderungen erfüllt. Entscheidend sind dabei Funktionen wie Bildspeicherung, passende Lichtquellen und die Einsatzhäufigkeit. Profitieren Sie von unserer Erfahrung und lassen Sie sich individuell beraten – so bekommen Sie die optimale Lösung für Ihre Anwendung.