In everyday work, problems in pipes are rarely immediately visible. Deposits, cracks, or leaks develop hidden from view and only become noticeable when problems arise—whether in the form of backups, odors, or even damage to buildings. Traditional methods quickly reach their limits here, as the causes lie deep within the system. This is precisely where a pipe camera becomes a crucial tool for reliable diagnosis.

Whether in sanitary areas, construction projects, or maintenance, a pipe camera provides you with reliable clarity without having to break open structures.

Our pipe cameras are designed for professional use and combine robust technology with practical details. They help you carry out inspections reliably, quickly, and with clear results—even under difficult conditions.

You are likely to encounter EViScopes pipe cameras in more areas than you might think at first glance. In the food industry, for example, pipes need to be inspected regularly—thoroughly, without shutting down entire plants. In energy supply, it is important to quickly check shafts or cable ducts before a small defect has major consequences.

In chemical plants or large industrial facilities, it is also crucial to be able to see what is hidden in order to be able to react in time. A pipe camera not only saves you time, it also provides clarity where you would otherwise be left in the dark. And let's be honest: who wants to rely on guesswork when it comes to protecting their own workforce and product (and production) safety?

Whether you need a video endoscope, UV lamp, or camera system, we can supply everything you need for your visual inspection. Tailored to your requirements. Direct, robust, reliable. Let our experts advise you now. We can help you select and use your inspection technology correctly.

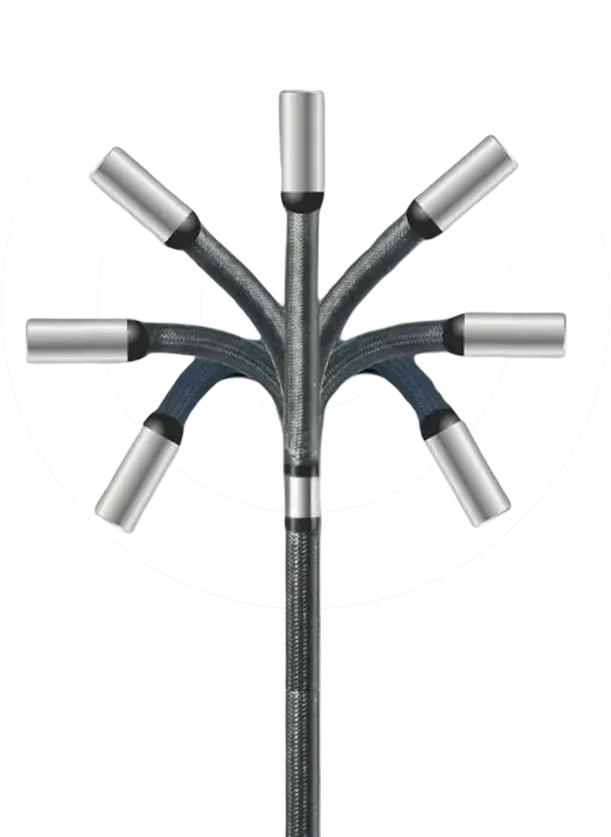

EViScopes pipe cameras are designed to adapt to your work—not the other way around. A high-resolution screen shows you even the smallest changes, while compact camera heads reach tight spots that you would never be able to access without technology. Different cable lengths are available for long distances, robust enough for everyday use yet flexible in handling. Dark shafts?

The integrated LEDs illuminate every pipe. Want to examine details more closely? A zoom or swivel head makes it possible. In addition, there are waterproof housings that remain reliably sealed even in damp or chemically contaminated environments. All in all, this is a tool that makes your everyday life easier and pays off in the long term.

Because we offer more than just a clear view

Especially when it comes to pressure vessel testing or machine maintenance: if you see changes early on, you can take action in good time.

No messy paperwork, no need to submit documents later—the results can be saved, tracked, and presented immediately. This is particularly important for providing evidence to authorities or customers.

In quality assurance, the difference between “looks good” and “is flawless” sometimes makes all the difference. Good images help with decision-making.

When several people review together—live or with saved images—decisions can be made faster and more clearly. This saves time and reduces stress.

EVi Scopes is for everyone

Interior views of machines, systems, and piping systems-non-destructive, directly documentable, and ideal for narrow or hard-to-reach areas in operation.

Making the finest structures visible – for technical inspection or preparation of devices, for example during endoscope reprocessing or cleaning control.

Maintenance, testing, and analysis of engines, components, or interiors-precise, safe, and without removal, even with tight tolerances.

Regular visual inspections help to prevent downtime. With the right technology, you can detect deposits, material wear, or damage at an early stage.

Safe inspection in pipes, tanks, or valves—even in hot, humid conditions or with limited access. Technology that can withstand harsh conditions.

Whether corrosion control in the engine room or visual inspection below deck – ideal for hard-to-reach areas on board and in shipyards.

FAQ

Because many people are interested: Here you will find practical answers to frequently asked questions about our product portfolio and our services—explained in an understandable way, directly from practical experience.

Questions? We're happy to help.A pipe camera is basically your eye in places you would otherwise never be able to reach. The camera is inserted into pipes or ducts via a flexible cable and shows you live what is going on there. This allows you to quickly see whether it is a simple blockage, whether roots have grown in, or whether a pipe is already damaged. The advantage is obvious: instead of tearing open or digging on suspicion, you can see the cause directly. This saves time, money, and a lot of stress.

The answer depends greatly on the model. Many pipe cameras are designed to be used in pipes with a diameter of around 30 millimeters or more. This makes it easy to inspect domestic installations. At the other end of the scale, there are systems that can reliably inspect main pipes or large sewers with diameters of up to 600 millimeters. It is crucial to choose the right camera for the application. Simply ask yourself: Do I tend to work in narrow supply pipes, or do I need a system for large industrial plants?

Cable length is one of the most important factors when choosing a pipe camera. Standard models are equipped with cables between 30 and 120 meters long (known as push cables). For smaller tasks, such as in buildings or domestic installations, 30 to 40 meters is usually sufficient. In industrial plants or municipal areas, longer ranges are required in order to inspect larger sections of pipe. Important to know: tight bends or deposits in the pipe can reduce the effective length. That's why robust yet flexible cables are crucial for reliably reaching even difficult sections.

A pipe camera provides one thing above all else: clarity. You can see exactly what is going on inside the pipe-without lengthy speculation or unnecessary construction work. This means that damage can be located precisely and repaired in a targeted manner. This is also helpful for documentation purposes: photos or videos show customers, authorities, or colleagues exactly what the situation looks like. In addition, regular inspections help prevent costly consequential damage. Ultimately, it's like a check-up: it's better to take a look early on than to experience big surprises later.