Imagine you had to thoroughly test a turbine, a pressure pipe, or a weld seam—and then everything still had to remain intact. Sounds like a contradiction? It's not. That's exactly what non-destructive testing (NDT) is for. It's a clever way to detect weak points early on-without damaging the component or disrupting operations.

And best of all, you retain full control without having to touch the technology. NDT means testing without destroying-no drilling, no cutting, no dismantling. Instead, methods such as ultrasound, eddy current, or dye penetration testing are used. Or modern video endoscopy-wherever visibility counts.

EVi Scopes not only make your pressure vessel inspections safer, but also less complicated. Our technology and consulting services enable you to proceed in a targeted, efficient, and legally compliant manner-without major interventions. Your advantages at a glance:

In short: because it's about safety. Specifically, real, measurable safety in systems where errors can have serious consequences-think of pressure vessels, pipelines, turbines, or power plants. A small crack in the wrong place, left undetected, can have major consequences. That is precisely why NDT is required by law in many areas – for example, in the Industrial Safety Regulation or the Pressure Equipment Directive.

But NDT also makes economic sense: early detection saves money later on. And good documentation ensures legal certainty. It may sound dry, but it's worth its weight in gold in everyday life.

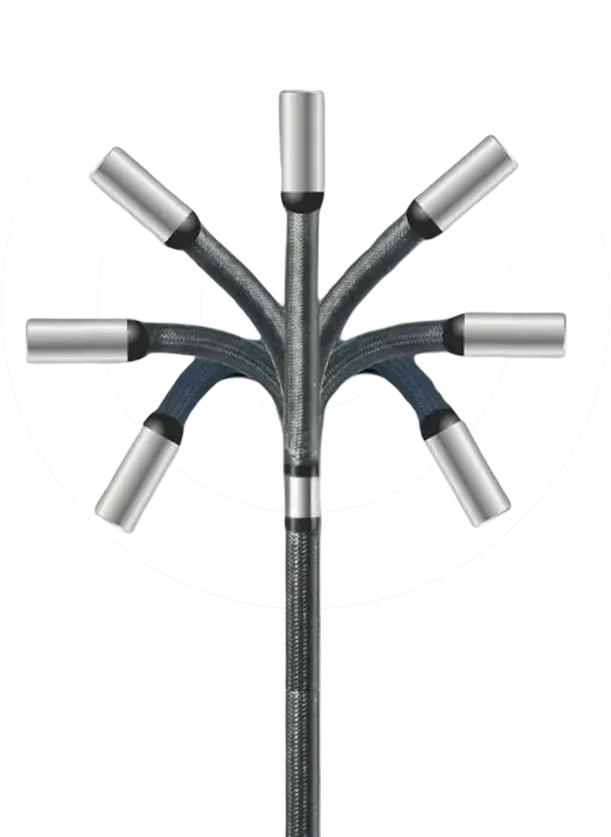

Whether you need a video endoscope, UV lamp, or camera system, we can supply everything you need for your visual inspection. Tailored to your requirements. Direct, robust, reliable. Let our experts advise you now. We can help you select and use your inspection technology correctly.

NDT is not “one” method—it is a whole toolbox. Depending on the material, location, test objective, or regulation, different methods are used:

And best of all, many of these methods can now be carried out on the move, automatically, or even online during operation without dismantling or stopping production.

Because we offer more than just a clear view

Especially when it comes to pressure vessel testing or machine maintenance: if you see changes early on, you can take action in good time.

No messy paperwork, no need to submit documents later-the results can be saved, tracked, and presented immediately. This is particularly important for providing evidence to authorities or customers.

In quality assurance, the difference between “looks good” and “is flawless” sometimes makes all the difference. Good images help with decision-making.

When several people review together-live or with saved images-decisions can be made faster and more clearly. This saves time and reduces stress.

EVi Scopes is for everyone

Interior views of machines, systems, and piping systems-non-destructive, directly documentable, and ideal for narrow or hard-to-reach areas in operation.

Making the finest structures visible – for technical inspection or preparation of devices, for example during endoscope reprocessing or cleaning control.

Maintenance, testing, and analysis of engines, components, or interiors—precise, safe, and without removal, even with tight tolerances.

Regular visual inspections help to prevent downtime. With the right technology, you can detect deposits, material wear, or damage at an early stage.

Safe inspection in pipes, tanks, or valves—even in hot, humid conditions or with limited access. Technology that can withstand harsh conditions.

Whether corrosion control in the engine room or visual inspection below deck – ideal for hard-to-reach areas on board and in shipyards.

FAQ

Weil es viele interessiert: Hier finden Sie praktische Antworten auf häufige Fragen rund um unser Produktportfolio und unsere Dienstleistungen – verständlich erklärt, direkt aus der Praxis.

Fragen? Wir helfen gernePut simply: whenever a container is under pressure and used in everyday life-whether for gases, steam, or liquids. Whether it's a liquid gas tank in industry or a compressed air cylinder in a workshop-the Industrial Safety Regulation applies everywhere. It stipulates who has to carry out inspections, when they have to be carried out, and exactly what has to be done. It may sound dry at first, but there is real responsibility behind it. Those who inspect protect employees, machines, and the environment. And those who don't? They risk fines, accidents, and legal trouble. So don't put it off. It's better to ask honestly.

That depends greatly on the container-but usually it starts with an external inspection: Are there any signs of rust, dents, or changes? Then, if necessary, we get down to the nitty-gritty-the inside. Fortunately, this can now be done without dismantling the container, for example with video endoscopes. For critical systems, a strength test or a non-destructive procedure is also carried out. It is important that the container is empty and clean beforehand. In the end, there is always one thing: a clearly documented result that shows whether everything is in order – or whether action is needed. Sounds technical? But it is feasible – and we are happy to help.

We hear this question often-and the answer is: it depends. Factors such as design, contents, pressure, volume, and risk are decisive. Sometimes an inspection every five years is sufficient. In other cases, another inspection is due after just one year. The basis for this is a risk assessment – i.e., an evaluation of how risky the operation of the container is. What many people forget is that the deadline starts from the date of commissioning, not when something happens. Our tip? Don't put off appointments and, ideally, integrate them directly into the maintenance schedule. Then everything will run smoothly.

The short answer: not just any specialist. Pressure tests are regulated by law-and, depending on the risk, clearly assigned. Visual inspections can be carried out by specially trained, so-called “qualified persons.” For anything more in-depth-for example, systems that require monitoring-official bodies such as TÜV or DEKRA come into play. They have the expertise, the equipment, and the legal basis. If you feel unsure about this, don't worry. At EVi Scopes, we advise you on what is important-and are also happy to help you organize the test.