Every detail counts in manufacturing. But if you inspect without a video endoscope or camera system, fine cracks or unclean weld seams can easily go undetected. The result is rejects, complaints, or, in the worst case, recalls. Documentation also becomes a test of patience: reports are missing, images are unclear, decisions take time. This costs time that no one in production has. Wouldn't it be easier to make problems visible before they cause trouble?

Every detail counts in manufacturing. Perhaps you are familiar with this situation: a workpiece looks fine at first glance, but a small crack or an unclean weld seam becomes apparent later on. This is exactly where EVi Scopes' high-tech products come in. They deliver razor-sharp images, make the invisible visible, and give you confidence in your decisions. At the same time, you have the documentation immediately at your fingertips. This saves you discussions and time. What would it be worth to you to discover errors before delivery?

Whether in the automotive industry, aviation, or plant engineering—strict requirements apply everywhere. The advanced video endoscope technology from EVi Scopes helps you to comply fully with norms and standards. Each test step can be visually documented and integrated into test reports. This allows you to provide transparent evidence to customers, auditors, or authorities at any time. This creates trust and gives you legal certainty in everyday production.

Detect errors in good time, document them, and make reliable decisions-that's exactly what our devices are designed for. Whether it's a weld seam, a borehole, or a final inspection: clear images give you a complete overview at all times. Enquire here directly and find out how EVi Scopes can support your quality assurance.

Industry 4.0 is changing manufacturing-and with it, quality assurance. With video endoscopes from EVi Scopes, every inspection step is digitally documented, annotated, and integrated into existing systems. Results can be shared immediately and archived in a traceable manner. This gives you speed in manufacturing, legal certainty in verification, and clarity in every production decision.

State-of-the-art quality assurance and production control

There is always little time available in production. All EVi Scopes products are designed so that checks can be carried out without lengthy training.

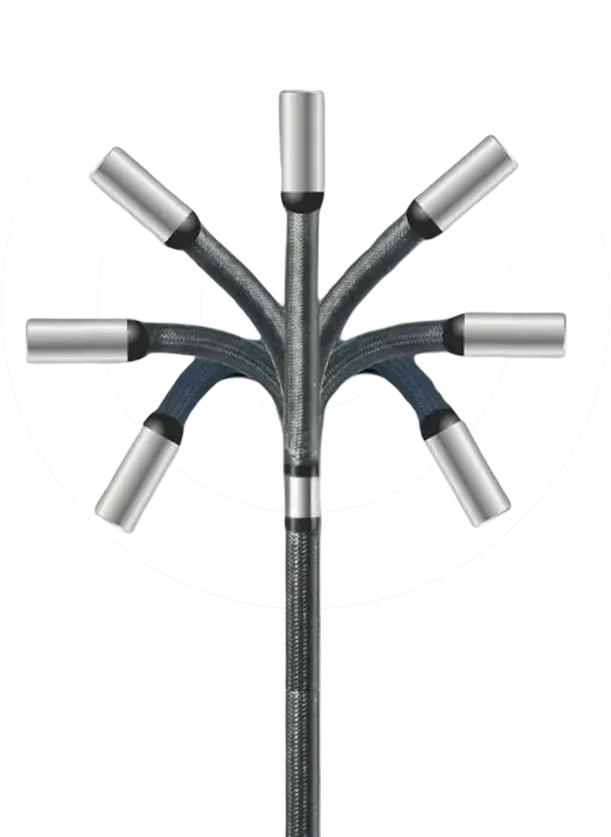

Whether small holes, large weld seams, or complex geometries—thanks to the right accessories and variable probes, you can cover many areas of application with a single system.

Quality assurance often means performing the same tests day after day. Our systems are designed for continuous use. They run smoothly, even with a high number of tests.

In addition to standard reports, you can document results exactly as your customers or auditors expect. Images, comments, markings—all directly on the device.

EVi Scopes is for everyone

Interior views of machines, systems, and piping systems—non-destructive, directly documentable, and ideal for narrow or hard-to-reach areas in operation.

Making the finest structures visible – for technical inspection or preparation of devices, for example during endoscope reprocessing or cleaning control.

Maintenance, testing, and analysis of engines, components, or interiors—precise, safe, and without removal, even with tight tolerances.

Regular visual inspections help to prevent downtime. With the right technology, you can detect deposits, material wear, or damage at an early stage.

Safe inspection in pipes, tanks, or valves—even in hot, humid conditions or with limited access. Technology that can withstand harsh conditions.

Whether corrosion control in the engine room or visual inspection below deck – ideal for hard-to-reach areas on board and in shipyards.

In addition to video endoscopes and borescopes, production control requires other products that make your inspections even more efficient.

FAQ

Quality is not an extra, but the basis of every manufacturing process. Here we answer questions that arise in everyday life when it comes to quality assurance and production control with video endoscopes.

Questions? We're happy to help.Perhaps you are familiar with this scenario: a component looks flawless at first glance, but a tiny crack renders it unusable. Such defects are easy to overlook when inspecting with the naked eye alone. Video endoscopes can reach places that no one else can see: inside boreholes, behind weld seams, in narrow cavities. They detect problems before they reach the customer. This reduces waste, saves material, and ensures that quality is not left to chance.

“We checked” – this is a phrase you often hear when documents are missing. With digital documentation, there are no more discussions. Every check is documented with images or videos, saved, and can be immediately transferred to reports. This provides you with evidence for customers, authorities, and your own records. Internally, things run more smoothly because everyone is working with the same information. No more guesswork, no more lengthy explanations. Just clear results that speak for themselves.

In many industries, it is not enough to have done a good job. It must also be verifiable. Whether it's TÜV, ZÜS, or other agencies—they expect clear evidence. With video endoscopes, you can document inspections in a way that is legally compliant. You don't just provide numbers on paper, but images that make the condition visible. This speeds up approvals and reduces queries. Those who provide comprehensible evidence of inspections ultimately save time and avoid discussions.

Mistakes are costly-anyone who has ever had to deal with rejects or rework knows that. Product recalls are even worse. Video endoscopes and borescopes allow you to identify problems early on. An unclean weld spot is noticed during inspection, not only when the customer receives the product. Decisions are made faster and processes run more smoothly. Less rework, less material waste, lower costs. Quality assurance is therefore not only a duty, but also an investment in profitability. Or to put it another way: what costs more – thorough inspection or having to recall products later?