Perhaps you are familiar with this scenario: The machine runs smoothly for months-until it suddenly stops working from one day to the next. Without modern inspection technology, much remains unknown. Deposits, corrosion, or small cracks often only become apparent when it is already too late. Then it's time to disassemble, maintain, and carry out expensive repairs. Unplanned downtime is not only stressful, but often also very costly. How do you deal with such surprises today?

Imagine having to loosen screws or shut down entire machines for every minor inspection. That would not only be annoying, but also expensive. With EVi Scopes devices, things are much more relaxed. You take a look inside, spot deposits or corrosion in good time, and can take action before the situation becomes critical. This makes maintenance predictable—no more panic reactions when something suddenly comes to a standstill. Sound helpful for your everyday work?

When inspectors from TÜV or ZÜS come by, it's not just your word that counts, but clear evidence. With EVi Scopes devices, you can document maintenance and repairs in such a way that all requirements are fulfilled in a legally compliant and traceable manner. Images and videos show the actual condition – legally compliant, archived, and accessible at any time. This gives you security and saves time during inspections.

With our video endoscopes, you can identify problems before they become costly. No endless downtime, no unnecessary dismantling—just clear results that help you move forward. Contact us now and let's discuss how we can make your maintenance easier and more predictable.

Today, maintenance means more than just tightening screws. With EVi Scopes products, you can save images and videos directly, create reports automatically, and share results with your team-even remotely. This makes every maintenance task more transparent, speeds up decision-making, and helps you operate machines in a more predictable and reliable manner.

This is how maintenance and servicing work today

Whether in a factory hall, on a construction site, or in narrow shafts: EVi Scopes devices are compact and robustly built. This allows them to be taken directly to the machine for immediate testing.

Dust, oil, moisture—these are typical companions in maintenance. Our systems are designed to work reliably even in harsh environments.

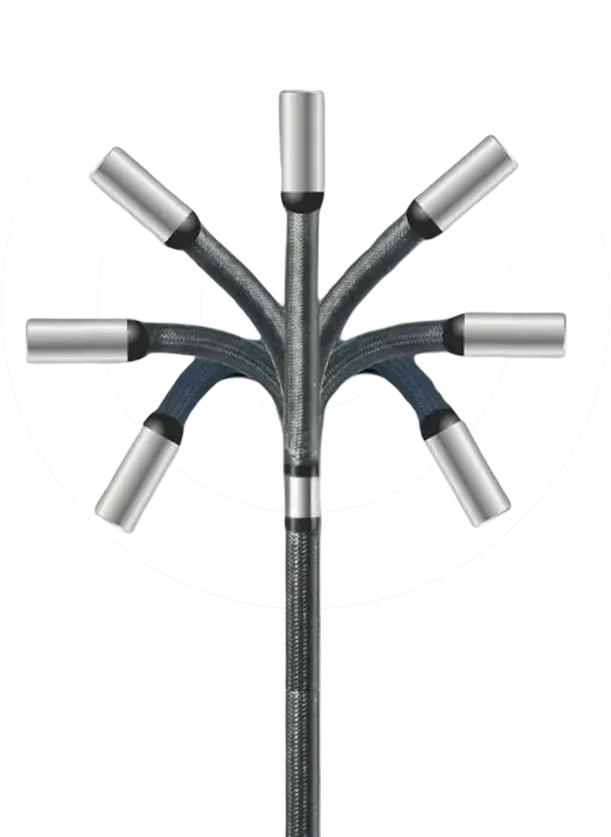

Every machine has its own characteristics. With flexible shafts, interchangeable camera attachments, or special lighting, you can inspect precisely where it would otherwise be impossible.

When speed is of the essence, every detail counts. Our video endoscopes start up without lengthy setup, deliver images immediately, and are so easy to use that even inexperienced hands can handle them.

EVi Scopes is for everyone

Interior views of machines, systems, and piping systems-non-destructive, directly documentable, and ideal for narrow or hard-to-reach areas in operation.

Making the finest structures visible – for technical inspection or preparation of devices, for example during endoscope reprocessing or cleaning control.

Maintenance, testing, and analysis of engines, components, or interiors—precise, safe, and without removal, even with tight tolerances.

Regular visual inspections help to prevent downtime. With the right technology, you can detect deposits, material wear, or damage at an early stage.

Safe inspection in pipes, tanks, or valves—even in hot, humid conditions or with limited access. Technology that can withstand harsh conditions.

Whether corrosion control in the engine room or visual inspection below deck – ideal for hard-to-reach areas on board and in shipyards.

In addition to video endoscopes and borescopes, our range includes practical accessories that make inspections faster and more reliable.

FAQ

Maintenance sounds boring—until something breaks down. Then you realize how important it is. Here you will find answers based on practical experience that can make your everyday maintenance and repair work easier.

Questions? We're happy to help.Imagine a machine that has been running for years-and then suddenly a pipe bursts. With a video endoscope, you might have seen the corrosion developing months ago. Such devices reveal deposits or hairline cracks before they cause damage. You save yourself the trouble of completely dismantling the machine and avoid unplanned downtime that could paralyze your operations. The bonus: you get crystal-clear images that you can save directly. That way, you have proof in your hands when someone asks, “Was that really necessary?”

Be honest: who hasn't lost notes on scraps of paper? That doesn't happen with digital documentation. Photos and videos are stored directly on the device, can be annotated, and immediately incorporated into reports. No more chaos with scraps of paper, no more addenda. When authorities or auditors request evidence, you have everything at your fingertips. It also works better in a team—results can be shared and discussed immediately, without any long detours. You gain clarity and save time. Sounds like a relief, doesn't it?

Operational safety is not a matter of luck, but of prevention. A small crack, discovered in time, can be repaired quickly. If you overlook it, it becomes a real problem. With video endoscopes, you can detect such changes early on. This reduces the risk of sudden equipment failure. And it's not just machines that benefit—the people who work with them every day are also safer. In short, you gain peace of mind because you know you're not driving blind.

Of course, maintenance costs money. But unplanned downtime costs many times more. Spare parts, technicians, lost production—the bill can quickly run into five figures. With our high-tech devices, you have it in your hands: you repair specifically, rather than on suspicion. At the same time, you extend the service life of your equipment. Maintenance intervals can also be planned more intelligently because you have real findings instead of just calendar dates. In the end, the question remains: would you rather invest in control and prevention – or in the consequences of failures?